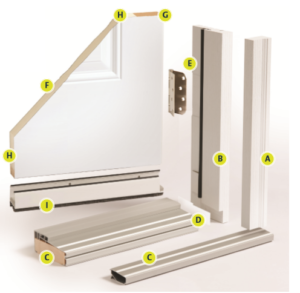

Humphrey’s Doors are built to last. Here’s why!

A) Composite technology solid brickmould

- Moisture and rot resistant

- Brickmoulds come in wood grained white and stainable tan as well as vinyl wrapped “wood” option

- Made to measure “built out brickmould” option available to suit special requirements

B) Composite technology solid door jamb

- Moisture and rot resistant

- Jambs available in wood grained white or stainable tan

- Vinyl wrapped finger jointed “wood” option as an affordable alternative

C) Heavy duty sill assembly

- Durable PVC thermal break, solid sill blocking, extruded aluminum threshold and nosing

D) Corner Sill Assembly

- Gasket and sealed sill corners, ensure tight connections that prevent air and water penetration Hinges

E) Hinges

- Heavy duty plated ball bearing hinges ensure smooth easy operation, in brass, nickel and black

- Adds beauty and guaranteed not to rust

F) High-density polyurethane core

- Provides superior insulation value and helps reduce sound transmission

G) Composite edges

- Composite edging prevents moisture from penetrating into the door slabs cavity to a much greater degree than normal wood edges

H) LVL stiles and rails

- Laminated veneer lumber (LVL) provides added rigidity, are moisture resistance and not as susceptible to twist or warp like regular finger jointed wood components

I) Adjustable Sweeps

- Rigid PVC door sweeps provide added protection against the elements